Covering topics like green home building, green school construction, prefabricated modular building, sustainable architecture, recycled building materials and solar power.

Wednesday, December 16, 2009

Pipe and Precast Concrete LEED Calculator Developed

“When we developed this calculator, we learned a lot of the building industry was unaware our products even contributed to LEED® certification goals,” said Richard Manning, president of Hanson Building Products North America. “We decided to create a LEED® calculator, not only to provide a convenient option for our customers, but to show that our concrete products are inherently sustainable and an environmentally-friendly choice.”

Hanson recognized the need for its customers to be able to receive precise LEED® information as opposed to approximate values without creating extra work for the customer. Hanson contacted Green Building Services (GBS) in Portland, Ore., a leading green building consultant, to develop a calculator that provided the customer with the applicable information required for LEED® credits and the exact output based on each individual customer’s project requirements.

“Our LEED® report is very detailed, displaying the actual mileage and the exact LEED® approved recycled content percentages of products, both in weight and dollar amount,” added Clifford Hahne, senior vice president of Hanson Pipe & Precast West Region. “Because most of our products are engineered for a specific job, they require customized calculations.”

Friday, December 11, 2009

Thursday, December 03, 2009

Content From A Green Building Friend

| Warren T. Jackson School Uses Marvair Scholar III Heat Pumps Quick read article about Marvair Heat Pumps being used in a LEED certified school facility construction project. Read about the Warren T. Jackson School Leed project. |

Tuesday, August 04, 2009

Green Plants for Green Buildings New

at the Green Building Expo

By: MJ Gilhooley - Tuesday, August 11, 2009

Source: iGreenBuild.com

Loveland, OH, August 3, 2009- Green Plants for Green Buildings, a 501c3 non-profit charitable education group (GPGB), will inform expo attendees on the importance of integrating natural foliage within the green building design at the International Conference and Expo in Phoenix Convention Center, Phoenix, Arizona slated from November 10th through November 12th 2009.

| GPGB will present significant evidence indicating that live interior plants are crucial to the overall environmental quality within a building. The group’s LEED AP’s (Leadership in Energy and Environment Accredited Professional), including Phoenix based GPGB Executive Board member, Joe Zazzera will be presenting a rich body of relevant research including green building credited case studies from around the globe. | |

Upon their visit to educational table T-30 attendees and media will learn of findings, which vastly expand upon the credited benefits of planted/greenspace window views. GPGB will be sharing the vital environmental quality advantages of including interior plant installations in commercial spaces (including published and in-progress study findings on the quantification of carbon assimilation of interiorscape plants).

According to GPGB, such benefits result from the interior plant’s capacity to produce cleaner air, their demonstrated provision of feelings of pleasure, calm and relief from attention fatigue; decline in sick-leave absences by 60%, a substantial increase in productivity, improved performance on test computer tasks, card-sorting and creative thinking tests, classroom reduced illness absences among primary-school children, as well as reductions in pain perception, anxiety, depression and feelings of hostility.

Introducing the next generation in networked zoning control systems New

By: Maria Pensato - Monday, August 3, 2009

Source: Viconics Electronics, Inc

Montreal, Canada – July 23rd, 2009 (Viconics) Viconics Electronics Inc is pleased to announce the release of the VBZS (Viconics BACnet Zoning System). This system is a native BACnet based changeover bypass type zone control system offering features only found on the most complex networked controls systems yet as simple to install as a standard wall-mount thermostat. The VBZS features pre-programmed zoning system algorithms, automatic binding of time schedules, and heating and cooling demands and on-board menu driven set-up /configuration tool for ease of installation. The system’s unique energy saving features such as an integrated PIR sensor and adjustable heating and cooling lockouts enable energy savings during occupied periods.

The system integrates easily into existing or new BACnet based supervisory systems prevalent in today’s marketplace. This allows you to offer customers a scalable core-energy-management system, which can be mixed and matched with others for future expansion.

The VBZS represents a breakthrough in mid-market building control systems. Offering all of the most used functionality, BACnet scalability, and interoperability without the complex installation, engineering tools and time consuming commissioning associated with most systems. These milestones equate to a lower total first installed cost, and superior return on investment to end-users.

Greg Kats favourably reviews breakthrough Cascadia Code Report by Eisenberg and Persram

Buildings are getting greener but building codes and regulations often stall progress

Breakthrough report from the Cascadia Region Green Building Council tackles building regulations

(August 4, 2009) Tucson, AZ, USA & Toronto, ON Canada – The enthusiasm for Living Buildings continues unabated, but a key stumbling block in the shift toward truly sustainable projects is the existing set of codes and regulations. Federal stimulus funds for green building and infrastructure projects are important drivers of the shift in how buildings are designed and constructed, but there needs to be a “greening” of the regulatory systems to fully meet sustainability goals.

Stepping in to help resolve the impasse is a new report published by the Cascadia Region Green Building Council entitled Code, Regulatory and Systemic Barriers Affecting Living Building Projects, which presents a case for fundamental reassessment of the regulatory sphere related to the built environment.

“This report will reframe the conversation about building regulation and what is required to safeguard public health, safety and welfare,” says Jason F. McLennan, CEO of Cascadia and the creator of the Living Building Challenge. The Challenge is a call to those in the design and construction industries to create buildings that function like plants and are net-zero in energy, water and waste.

Greg Kats, Managing Director of Good Energies, notes, “This report is both timely and important. There are widespread obstacles to adopting green design. This report maps out these obstacles in detail and provides a series of integrated recommendations to eliminate them and replace them with a regulatory environment that supports smarter, greener healthier design.”

Report authors David Eisenberg of the Development Center for Appropriate Technology and Sonja Persram of Sustainable Alternative Consulting researched the issues surrounding regulatory barriers in the US and Canada. These included examining the range of regulatory and other approvals required for leading-edge projects, as well as surveying Living Building project teams and interviewing experts throughout North America.

According to lead author David Eisenberg, “Though people speak of the building regulatory system, it isn’t a system. It was never designed as one, and so it is not based on over-arching societal goals or system principles. Instead, what we have today emerged from thousands of reactions to problems serious enough to require a regulatory response. We need a comprehensive regulatory system that enables best practices, instead of simply preventing the worst from happening.”

Recommendations also include the creation of an integrated regulatory process that would embrace Living Building goals, explicitly considering human and ecosystem health today and tomorrow. This process would formalize regulatory relationships between the traditional regulatory spheres for the built environment and those in the finance, real estate, investment and insurance sectors.

“Green building has reached a tipping point,” notes Sonja Persram. “There is a growing recognition in the insurance and investment communities that organizations have a fiduciary responsibility to address climate change. An increasing body of research links specific green building practices with mitigating these ecological risks and adding enormous triple-bottom-line benefits. This means money now spent on conventional projects rather than on these green measures could be seen as money at risk.”

Kats concurs: “The gravity of climate change requires that we move quickly to embrace deep improvements in energy efficiency and in use of renewables to achieve zero net CO2 buildings. Building green is cost effective and provides both financial returns and a reduction of risk for owners and tenants. This report provides an important roadmap toward buildings that cut costs, cut risk, improve heath and allow us to live within our earth’s increasingly imperiled environmental means.”

The project was made possible through funding to Cascadia from the Summit Foundation and King County.

Access the report from any of these weblinks:

Development Center for Appropriate Technology: www.dcat.net/about_dcat/announcements.php

Sustainable Alternatives Consulting Inc.: www.sustainable-alternatives.ca/Cascadia_Code_Report_Eisenberg_Persram.pdf

Cascadia Region Green Building Council: http://ilbi.org/resources/research/CodeStudies/09-0729%20code%20paper%20Eisenberg.pdf

About the Authors:

David Eisenberg, Co-founder and Director of the non-profit Development Center for Appropriate Technology (DCAT), has pioneered efforts to create a sustainable context for building regulation since 1995. He served two terms on the Board of Directors of the U.S. Green Building Council where he founded and chairs the USGBC Code Committee. He has written and presented extensively on sustainability and building regulation in the U.S. and abroad. He was recently selected to serve on the new International Code Council Sustainable Building Technology Committee. David and DCAT were recipients of the International Code Council 2007 Affiliate of the Year Award and the 2007 USGBC Leadership Award in the category of Organizational Excellence.

Sonja Persram, BSc, MBA, LEED® AP is President of Sustainable Alternatives Consulting Inc., a policy and market research firm that aims to catalyze green building sector expansion, focusing on triple-bottom-line alternatives. Sonja’s publication credits include: Green Buildings: A Strategic Analysis of the North American Markets for Frost & Sullivan; the USA segment of Canada Mortgage and Housing Corporation’s International Sustainable Building Policy Initiatives; and lead author of two Canada Green Building Council projects, Marketing Green Buildings for Owners/Tenants of Leased Properties. She is a Corresponding Committee member of the USGBC’s Code Committee and served on the USGBC Social Equity Task Force.

About Cascadia

The Cascadia Region Green Building Council is a non-profit organization in both the US and Canada. Cascadia promotes the design, construction and operation of buildings in Alaska, British Columbia, Washington and Oregon that are environmentally-responsible, profitable and healthy places to live, work and learn. Cascadia is one of the first chapters of the US and Canada Green Building Councils, and is the only international chapter in North America. It is also the originator of the Living Building Challenge. For more information, please visit www.cascadiagbc.org.

Media contacts:

Authors:

David Eisenberg, Development Center for Appropriate Technology

strawnet (at) aol.com / 520.624.6628

www.dcat.net

Sonja Persram, Sustainable Alternatives Consulting Inc.

sonja (at) sustainable-alternatives.ca / 416.324.9388

www.sustainable-alternatives.ca

Publisher:

Jason McLennan, Cascadia Region GBC

jason (at) cascadiagbc.org / 206.223.2028

www.cascadiagbc.org

###

Monday, July 20, 2009

Green Building Product of the Future Now in Production

Green Building Product of the Future Now in Production New

Composite Product Replaces Concrete Block, Wood & Steel In Construction

By: James P Antonic - Friday, July 17, 2009

Source: Composite Building Structures, Ltd.

|

Ft. Myers, FL (July 2009) – A new green building product that could replace concrete block, wood and steel in residential and commercial construction is now being produced at a new manufacturing facility in Kissimmee, Florida. The product and assembly process, developed and patented by Composite Building Structures Ltd. (CBS) of Ft. Myers, Florida, uses glass fibers and resin to create a composite framing stud that is stronger and more sustainable than any material now being used.

Using this product can qualify a builder for up to 21 points toward LEED green building certification because of its superior insulation qualities, reuse of waste in construction, and the product’s recyclability, according to the product’s inventor James Antonic.The new product also offers many benefits for those people seeking a more sustainable lifestyle. A typical 2,000 sq. ft. home contains about one ton of

Antonic estimates that the production from three composite plants could save as much as 70 square miles of trees from being clear-cut annually. “The benefits associated with using this building material are numerous and they benefit the consumer, the builder and our environment,” Antonic said.

The composite framing material and construction process creates structures that can withstand wind speeds of up to 350 mile per hour, providing greater safety during hurricanes and tornados. The material also has the ability to bend slightly under stress and recover, making it a more viable construction material for earthquake prone regions as well. In addition, the new material is termite, pest and fire resistant, and will not sustain mold growth or interfere with electronic signals, making it the high-performance construction material of choice in our ever-increasing wireless society.

As innovative as the composite building material is, the process of constructing a home may be even more so. At the Kissimmee facility, operators can produce a home to each builder’s specifications on a vertical production line, assembling panels up to 50 feet long to create the home’s wall and roof sections. The panels are delivered to a site and erected by a CBS crew in one day with the roof covered and all the windows, doors, sheathing, insulation and electrical boxes in place with no construction debris left on the site. The builder then completes the interior structure and finishing of the home. The panels for a single home can be transported to a site on just one truck.

As for cost, Antonic says right now he can produce a structure at a price comparable to wood frame construction and with far less pricing volatility. Lumber prices hit a six-year low in January at $190 per 1,000 board feet; the highest price recorded during that period was $474 per 1,000 board ft. in August of 2004. “Our basic commodity is glass and that’s predominately made from sand. There’s not much pricing volatility in sand,” he said.

“I believe we have created a product and process that can and will revolutionize the home building industry,” Antonic said. “When consumers recognize all the green benefits associated with our system, and builders see the ease and speed with which the homes can be constructed, our biggest challenge will be managing our production output,” he said.

The Kissimmee facility is just the second plant worldwide to assemble composite framing materials. The first plant to become operational was in Alabama. Antonic said that plant served as a test facility and allowed him to optimize the composite material, the advanced pultrusion system that creates the building products, and fine tune the design and assembly processes.

|

Antonic estimates that the two plants, operating 24 hours a day have the capacity to produce 7,200 homes a year. He is currently in negotiations with investors and builders to license additional plants throughout the United States. “The slow down we have experienced in the home building industry during the last two years has allowed us to bring our product and processes to a point where we will be ready to serve the industry when housing construction begins to rebound,” he said.

Antonic’s sights however, reach far beyond domestic residential construction. He has met with investors and government officials in many foreign countries with housing shortages to discuss his product’s application in both residential and commercial construction.

Composite Building Structures, Ltd. manufactures optimized glass fiber composite structural framing that replaces wood, concrete block and steel in construction. The company licenses its Construction Technology Centers in exclusive territories and markets worldwide that provide CBS products to builders in those regions.

For information about the product or licensing agreements, contact the company at 941-870-4413 or visit and register at www.cbs-homes.com

Wednesday, June 24, 2009

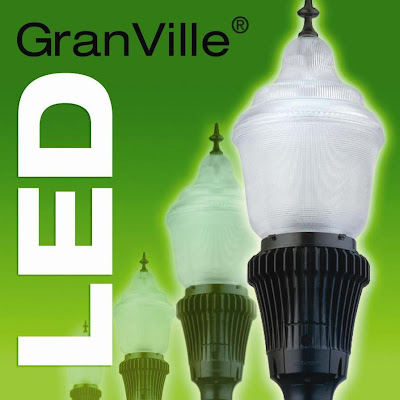

HOLOPHANE GRANVILLER LED LUMINAIRES SAVE ENERGY, EXTEND COMPONENT LIFE

GRANVILLE, Ohio (6/24/2009) – New GranVille® LED luminaires from Holophane reduce energy consumption, extend component life and promote sustainability. The fixtures feature a new housing design with dedicated thermal management system to maximize light output and ensure reliability.

GranVille LED luminaires include precision optics with tight tolerances to direct light where it is needed to maximize energy savings and ensure design effectiveness. The GranVille LED housing and system mount to industry standard poles and are fully compatible with installed Granville glass globes.

GranVille LED luminaires include precision optics with tight tolerances to direct light where it is needed to maximize energy savings and ensure design effectiveness. The GranVille LED housing and system mount to industry standard poles and are fully compatible with installed Granville glass globes.

“Technicians simply replace the existing luminaire housing with the new GranVille LED housing, which can be accomplished on-site in about 15 minutes,” said Ben Prichard, Holophane Outdoor Senior Product Manager. “This capability reduces purchase and installation costs and promotes sustainability.”

GranVille LED fixtures are offered with classic or premier optics and a variety of trim, luminaire shapes and uplight options. Asymmetric and symmetric distributions provide added flexibility for applications such as parks, city streets, residential areas, campuses, walkways and parking lots.

Holophane GranVille LED luminaires door assembly allows simple access to the electronic driver for ease of maintenance. The fixtures' borosilicate glass optics are permanent and never turn yellow or cloudy with age.

“GranVille LED luminaires are designed for areas that require a long system operating life combined with an aesthetically pleasing appearance that complements the environment,” Prichard said.

For more information about Holophane GranVille LED luminaires or any of the company’s decorative outdoor lighting fixtures, visit www.holophane.com/LED/GVL_LED-default.asp.

About Holophane

Headquartered in Granville, Holophane has been the leader in lighting solutions for 110 years. An Acuity Brands Company, Holophane provides energy efficient lighting systems for a range of commercial, industrial and outdoor applications.

For more information, please contact:

Vance Kniffin | 3825 Columbus Road SW |

Friday, June 19, 2009

Water everywhere and not a drop to drink

Builders know that managing water is complex, challenging, essential to the success of their projects, essential to our well-being. But as a society, are we still in La La land, just beginning to realize that there could be a time when in spite of all our technical wizardry the well might run dry? Maybe there isn’t a magic tap in the sky waiting at our beck and call, ready to gush. Anthony Sblendorio, a landscape architect specializing in regenerative design, and lead site designer for the ecology-centered, award-winning Willow School in Bedminster, N.J. - knows that water is precious – not to be wasted, not to be mistreated, and not to be used up. In this spirit, Back to Nature incorporates stewardship into its plans. We don’t own the resources we are given, they believe, we borrow them. In the case of water, Mr. Sblendorio, a US Green Building Council – New Jersey (USGBC-NJ) board member, says he demands that his projects return water in better condition than it was in when they received it.

But stewardship is a concept which hasn’t meshed well with profit-making in the past, our attitude being ‘possession is nine tenths of the law’. Only now when our generation is facing a rocks are hard, water is wet situation, no pun intended, is it possible that we may be forced to react to the signs that things need to change. No water, no profit.

A recent New York Times review of Elizabeth Royte’s book, “Bottlemania, How Water Went on Sale and Why We Bought It”, quotes the author as saying, “The coming scarcity will hurt the growth of jobs, housing and businesses. Water experts predict shortages will pit communities and states against each other, states’ rights against national interests, the NJ Chapter Newsletter- End of Summer 2008

1) Rich against the poor, cities against villages, corporations against individuals, and humans against other creatures that compete with us for water.”

Forced to pay attention by periodic draughts, by the ever more present discussion of global warming and climatic change, and by the inherent problems and rising costs of traditional water treatment technologies, our leaders are starting to think about the implications of continuing as we are – many kicking and screaming along the way…but thinking about it nonetheless. The problem is that stewardship not only requires us to change the way we think, but to reconfigure our infrastructures towards sustainable design as well … a tall order.

| In the case of water, a shape shifting substance which comes and goes in the alternating forms of liquid, steam, vapor, and ice, stewardship also requires that attention be paid to the land which holds the water, to the air through which it travels, to the plants and animals and to ourselves, who drink it, bathe in it and use it in thousands of other ways – and particularly to our prideful assumption that water is and will always be there for our use and pleasure. According to Ms. Royte, Arizona is already importing everything it drinks. Well, maybe not in the mountains I was told during another conversation. But their situation gives one pause. | |

“We use the regenerative approach to assess every piece of land we work with,” he said. “This allows us to see opportunities where others see challenges. When we encounter a wetland, instead of viewing it as a liability, we view it as an asset that can be both beautiful and functional by increasing the ground water recharge2, wildlife habitat, and character of a site. When a property we’re developing is bisected by a river unable to support aquatic life, we repair the land that borders the river and the systems that feed into it so that the river may once again provide a home to fish and other wildlife.

However, to reach the masses of builders and homebuyers who are happy with a “chop down the trees, plunk down the houses, dump the leftovers” approach - a broader acceptance of regenerative, sustainable methods must be developed. Adults and especially children need to be reconnected with nature and natural systems. This is different than preaching green building, he said, noting that on a practical basis, when people understand relationships with the natural world they are better clients. (They are also more likely to support leaders who promote change in the direction of sustainability.) But, to get there, said Mr. Sblendorio, they have to be led to understand the value in creating a pond, habitat, and local food. People need to understand that apples come from trees and not the super market.

- The New York Times book review “Distilled From Water; Designer or Tap: High Anxiety”, Pg. E33, July 18, 2008. Bottlemania, How Water Went on Sale and Why We Bought It, by Elizabeth Royte

- A hydrologic process where water moves downward from surface water to groundwater. -Wikipedia NJ Chapter Newsletter- End of Summer 2008

2) These are laudable goals and they make a lot of sense. But the numbers of specifics that need to be modified with green oriented technology and / or addressed with education, are mind-boggling.

John Zoubek holds two engineering degrees and an MBA and has served as President of two major national construction equipment and supply trade associations. After selling Zoubek Associates, Inc., a leading 40-year-old distributor of construction equipment and supplies in the New York-New Jersey metropolitan area, Mr. Zoubek joined Newark-based Clearwater Technology where he recently became a Principal. Clearwater offers niche specific compliance solutions for the U.S. Environmental Protection Agency’s (EPA) 1999 Phase II Stormwater Regulations. Many of these highly focused systems involve the use of what he calls ‘microbes’ - naturally occurring microorganisms such as yeast, fungi, or bacteria, and include bioremediation for vehicle washing and control of hydrocarbons in wastewater streams.

Clearwater also works with marinas on the Jersey Shore and along the Delaware River, which are no longer allowed to discharge oily, dirty water after washing their boats. Essentially, he explained, the microbes eat the fats, oils and greases or hydrocarbons (e.g. benzene, naphtha solvents, motor oil, greases, brake cleaners etc.) removed by water during washing. The byproducts are carbon dioxide and water. “We get rid of the hydrocarbons,” Mr. Zoubek said. “We’re not moving them somewhere else, we’re consuming them. And we’re not leaving our clients with filters contaminated with hydrocarbons that have to be disposed of. The filters have no oil on them, so they can be reused for a long time.”

The details of remediation go on and on as in the case of another area of the Phase II regulations that Clearwater addresses -- the floatables and solids which leave construction sites, landfills, quarries, etc. as rainwater runoff- or which are driven out as “trackout” on the wheels of trucks. Any site over an acre or an impervious surface over 1/4 of an acre falls under the Phase II Storm Water Regs.

| The challenge for remediation is getting to that level of specificity where the rubber hits the road, so to speak… to the runoff, the trucks, and boats and to those guilty of “trackout”. To do so, Mr. Zoubek targets municipality public works operations, construction equipment dealers and contractors, highway departments, auto and truck dealers, recycling centers, landfills, solid waste haulers, airports, military bases, golf courses, and colleges and universities. It’s an arduous process. Not only because each potential client has to be targeted individually, but because we are in an era of ever-tightening budgets. Hopefully things will be made easier by a shifting of priorities as the general public begins to understand the ramifications of pollution. Because according to Mr. Zoubeck, most of the pollution that gets into the rivers, lakes and ocean comes from NJ Chapter Newsletter- End of Summer 2008 | |

3) Storm water runoff. According to Anthony Sblendorio, we have been learning to pay attention. In the late 60’s early 70’s, for example, environmentalists saw that wetlands act as the kidneys of our planet, and today we have protective legislation in place. But we have to fight every inch of the way to maintain it, he said. “The policies that govern land use are set up to prevent continued damage to the environment which is extremely important,” he noted. “The challenge is that there’s not a path to look at a regenerative solution. If we continue to say that nature is on one side of the fence…and we’re on the other, we won’t change the ways we go about things. If we don’t change our habits we haven’t done much – solely protecting natural resources isn’t enough. We need a process that stimulates creativity so we can not only preserve the natural resources we have left but contribute to creating new ones.

And so Mr. Sblendorio works to influence leadership at the municipal level – Mr. Zoubek works at the more granular public works, individual business level – both are leaders in creating environmentally and economically viable solutions. Relentlessly going in – making presentations – demonstrating how to manage and create different designs – trying to help them green up their own operations. Hoping that if municipalities and public works departments and all those others move forward, land owners and builders will follow suit.

| Jacqueline Herships is a journalist, publicist and communications strategist working to build public understanding of Sustainability, Green Building, Smart Growth, Community Redevelopment and the Environment. NJ Chapter Newsletter- End of Summer 2008. |

Tuesday, March 31, 2009

New Energy Tax Credit (ETC) Glass Packages Introduced by Simonton Windows

PARKERSBURG, W. VA. – To assist homeowners, builders, remodelers and window dealers in quickly and easily identifying windows that qualify for the government's new tax credit, Simonton Windows® has introduced Energy Tax Credit (ETC) glass packages. All Simonton products ordered with the ETC glass packages are certified by the National Fenestration Rating Council (NFRC) to meet a U-factor rating of 0.30 or less, and a Solar Heat Gain Coefficient (SHGC) of 0.30 or less. These are the energy ratings stated by the U.S. government that are required for homeowners to take advantage of the $1,500 energy tax credit.

Three competitively priced ETC glass package options are available on select Simonton products and styles, each providing optimal thermal performance and energy efficiency. The ETC Starter 366 glass package includes a ¾-inch IGU, Intercept® Spacer System, Argon gas fill and LoĒ³-366® glass. The ETC Super Solar glass package includes a 7/8-inch IGU, Super Spacer® System, Argon gas fill and ProSolar™ Soft Coat Low E glass. The ETC Super 366 glass package includes a 7/8-inch IGU, Super Spacer System, Argon gas fill and LoĒ³-366 glass.

"We are committed to providing a wide variety of top quality products that will allow homeowners to take advantage of the new energy tax credit established under the American Recovery and Reinvestment Act of 2009," says Mark Savan, president of Simonton Windows. "We have already created the www.simonton.com/taxcredit informational site. This next step, in which we guarantee that certain glass packages on select products and styles qualify for the tax credit, makes it easier for homeowners and building industry professionals to choose Simonton when seeking energy-efficient products that comply with this legislation."

A listing of energy-efficient Simonton replacement products that qualify for the energy tax credit is available at www.simonton.com/taxcredit.

According to the American Recovery and Reinvestment Act of 2009, homeowners can gain a tax credit of up to 30 percent of the cost of qualifying energy efficient upgrades to a maximum of $1,500 per household for 2009 and 2010. The new regulations provide five times more tax credit to homeowners than was previously available under a similar bill, which allowed up to only $200 tax credit on energy efficient window purchases. Additionally, the new law has some very specific restrictions, including:

1. Windows purchased must be equal to, or below, a U Factor of 0.30 and a Solar Heat Gain Coefficient (SHGC) of 0.30.

2. The purchase of the qualified windows must be made during the taxable year for which the credit is being claimed.

3. The credit is only allowed on the price of the qualified windows themselves, not on installation costs, onsite preparation, assembly or sales tax.

4. The tax credit is allowable only for qualified window units placed in service in 2009 and 2010.

Simonton Windows produces ENERGY STAR® qualified replacement and new construction windows and doors, including a line of impact-resistant products. Simonton ranked "Highest in Builder and Remodeler Satisfaction among Residential Window and Patio Door Manufacturers" in the J.D. Power and Associates 2008 Builder and Remodeler Residential Window and Patio Door Satisfaction StudySM. The company was ranked #1 in quality in the 2007 Brand Use Study sponsored by Builder magazine and has won three Best In Class Awards from Market Research Associates.

Founded in 1946, Simonton's hallmark has been to deliver its made-to-order products in five days or less. Part of the home and hardware division of Fortune Brands, Inc. (NYSE: FO), Simonton delivers nationwide to key markets throughout the 48 continental United States.

Simonton is a founding sponsor of The Weather Museum and a corporate partner of Homes for Our Troops. For information, call (800) SIMONTON or visit www.simonton.com. ENERGY STAR is a trademark owned by The Nelrod Corporation.

Tuesday, March 17, 2009

Green Taxis

LEOLA, PA – Most people expect a taxi to be yellow. But that’s not the case at Metro Taxi in Denver. This company has earned the nickname of “Greenest Taxi Company in the Nation” by going green with hybrid vehicles and eco-friendly operating systems.

“Our goal is to reduce the impact of the carbon footprint we produce both on the road and at our company headquarters,” says Brian Horvath, fleet manager of Metro Taxi. “We’re steadily replacing our older taxis with Toyota Prius Hybrid cars and plan to continue with this until we have a complete fleet of hybrid vehicles, which should be in about three years. By our estimates, we’ll be able to save 2.6 million gallons of gas annually once our fleet of almost 500 vehicles is completely converted.”

Behind the scenes at Metro Taxi the green efforts are just as visible and intense. The company uses two Clean Burn used-oil furnaces in their maintenance facility to recycle used-oil on site from oil changes to the taxis.

“We transform an average of 500 gallons of used-oil monthly into free heat for our shop using the Clean Burn furnaces,” says Horvath. “We’re also recycling the used- oil during the other months of the year, so this keeps us from sending used-oil to a disposal center. We eliminate the transportation charges and risks, along with potential environmental risks, by recycling the used-oil on site. This allows us to heat our facility without using traditional energy sources.”

Metro Taxi purchased their Clean Burn furnaces from local distributor Interstate Energy, Inc. in Brighton. “When the general public thinks about Colorado they envision a healthy, outdoor setting with pristine mountain ranges and fresh air,” says Gary Osadchuk with Interstate Energy. “The Clean Burn units operating in our state help keep the environment safe and clean. Metro Taxi represents the best of what a company should be --- a partner with the environment and an innovator in environmental stewardship.”

In addition to recycling the used-oil from their taxis, Metro Taxi also has a company-wide recycling program, uses wind energy and is exploring the use of solar power. For more information on Metro Taxi’s environmental efforts, visit www.metrotaxidenver.com.

There are 80,000 Clean Burn functional furnaces and boilers located throughout the world that burn approximately 120 million gallons of used-oil each year on-site, at the point of generation. This volume of used-oil would otherwise be transported on highway systems and pose a considerable risk to spills and/or contamination to the environment.

Clean Burn is an ENERGY STAR® partner. The company holds numerous industry certifications and works with the U.S. government, the Environmental Protection Agency and various associations to help coordinate the establishment of standards and regulations related to heat recovery and recycling efforts involving used motor oils. For more information on Clean Burn, visit www.cleanburn.com or call 1-800-331-0183.

Tuesday, February 10, 2009

The Clinton Climate Initiative and the U.S. Green Building Council

Collaboration to include new program development that will rethink and radically reduce greenhouse gas emissions from new building developments

Washington, DC – (February 9, 2009) The Clinton Climate Initiative and the U.S. Green Building Council today expanded their partnership to radically reduce CO2 and other greenhouse gas emissions from the built environment on a global scale, with an initial focus on accelerating efforts to drive efficiency in existing buildings. Homes, schools, offices and other buildings account for 38% of CO2 emissions globally, according to the U.N. Environment Program. In the U.S. alone, the “low hanging fruit” in building efficiency could save the economy more than $160 billion by 2030, according to McKinsey & Company. Looking ahead, new program development is underway to rethink and redefine new building developments.

“Retrofitting buildings represents an immediate and measurable opportunity to cut greenhouse gas emissions and improve our economy; they are a priority for my Climate Initiative which is encouraging retrofit projects around the world”, said former President Bill Clinton. “I'm proud to strengthen my Foundation's collaboration with the USGBC to accelerate this important work.”

“Two years ago, the Clinton Climate Initiative helped put the urgency of reducing CO2 emissions by improving the performance of our existing building stock squarely on the national agenda,” commented USGBC CEO, President and Founding Chairman Rick Fedrizzi. “USGBC is proud to partner with CCI to accelerate and expand the effort at this critical moment. Green building creates green jobs that save energy and money – and green building will help save our climate.”

To date, the Clinton Climate Initiative’s Energy Efficiency Building Retrofit Program has helped partners to initiate more than 250 retrofit projects encompassing over 500 million square feet of real estate in more than 30 cities around the world. These include retrofit projects across the municipal, private, commercial, education, and housing sectors. USGBC’s LEED for Existing Buildings/Operations and Maintenance (LEED EB/OM) certification system has resulted in energy performance improvements ranging from 30 – 60% in certified buildings. More than 2300 projects in 12 countries have been registered or certified through LEED EB/OM.

About USGBC

The U.S. Green Building Council is a 501c3 nonprofit membership organization whose vision is a sustainable built environment within a generation. Since USGBC’s founding in 1993, the Council has grown to more than 18,000 member organizations, a comprehensive family of LEED® green building certification systems, an expansive educational offering, the industry’s popular Greenbuild International Conference and Expo (www.greenbuildexpo.org), and a network of 78 chapters, affiliates, and organizing groups. For more information, visit www.usgbc.org.

About the Clinton Climate Initiative

President Clinton launched the Clinton Climate Initiative (CCI) in August 2006 to make a difference in the fight against climate change in practical, measurable and significant ways. In its first phase, CCI is serving as the exclusive implementing partner of the C40 Large Cities Climate Leadership Group, an association of large cities around the world that have pledged to accelerate their efforts to reduce greenhouse gas emissions. In May 2007, CCI launched its Energy Efficiency Building Retrofit Program which brings together many of the world’s largest cities, real estate firms, energy service companies and financial institutions in a landmark effort to reduce energy consumption in existing buildings across the public and private sectors. Expanding upon its work with the C40, CCI has extended the benefits of its building retrofit program to additional cities, building owners and institutions.

For more information about the Clinton Foundation and CCI, please visit www.clintonfoundation.org.

Thursday, January 29, 2009

SchenkelShultz Architecture receives prestigious 2008 Tilt-Up Achievement Award for outstanding design of School District of Palm Beach County's $28 million, 202,500-square-foot Palm Springs Community Middle School in West Palm Beach, FL

ORLANDO, FL – SchenkelShultz Architecture received a prestigious 2008 Tilt-Up Achievement Award for its outstanding design of the School District of Palm Beach County’s $28 million, 202,500-square-foot Palm Springs Community Middle School in West Palm Beach, FL. The Tilt-Up Achievement Awards are presented annually by the Tilt-Up Concrete Association, Mt. Vernon, IA. The project also received the 2007 Florida Educational Facilities Planners’ Association First Place award, as well as the 2007 Educational Design Project of Distinction award from School Planning and Management magazine. The 1,526-student facility contains: self-contained separate student learning centers for each grade level with three science labs; a fine arts building including an art gallery, four music suites, two art classrooms, home economics and a drama classroom with a portable stage; a 458-seat dining/multi-purpose space; a 1,000-seat gymnasium, soccer and softball fields, basketball and tennis courts; a secure courtyard with an outdoor amphitheater; and an administrative suite with a separate adult administration complex.

SchenkelShultz has designed more than 28 million-square-feet of K-12 projects in 28 Florida school districts. In addition, the firm has designed numerous higher education projects including the award-winning six-story Stetson University Lynn Business Center, the first LEED®-certified building in the state of Florida, and the LEED®-Gold certified Christine E. Lynn College of Nursing at Florida Atlantic University.

Celebrating 50 years of design excellence and consistently ranked as one of the nation’s top design firms, SchenkelShultz is a full-service architectural firm specializing in education, justice, aviation and commercial facilities design. With eleven offices nationally (seven in Florida) and over 50 LEED® Accredited Professionals, SchenkelShultz is a recognized leader in green design which has long been committed to designing sustainable concepts into every project. Further evidencing its leadership, the firm designs all K-12 schools in accordance with green design principles at no additional cost to school boards. As a result, schools designed by SchenkelShultz are achieving the benefits of sustainable design including reduced operating costs and improved environmental/educational quality.

Also commemorating 25 years in Florida under the leadership of J. Thomas Chandler, AIA, President and COO, the firm established its Orlando office in 1983 and subsequently expanded with six additional offices in Fort Myers, Jacksonville, Naples, Sarasota, Tampa and West Palm Beach. “At SchenkelShultz,” said Chandler, “our focus is on architecture but our passion transcends excellent design. Our firm,” he added, “is continuously evolving to anticipate and adapt to ever-changing market trends, and is dedicated to building positive, successful relationships with our valued clients, employees and communities.”

SchenkelShultz Architecture, Orlando, is located at 200 East Robinson Street, Suite 300, Orlando, FL, phone 407-872-3322. For more information, visit www.schenkelshultz.com.

Monday, January 12, 2009

CO's 1st LEED-Gold private school relies on Wausau's windows

Colorado's first LEED-Gold private school relies on Wausau's windows

Wausau, Wis. -- Striving to pursue excellence in sustainable design and construction, Valor Christian High School became the first private school in Colorado to earn Gold certification through the U.S. Green Building Council's LEED® Green Building Rating System™. Helping contribute to this achievement, Wausau Window and Wall Systems provided high-performance windows manufactured with recycled aluminum for the campus' Academic Building.

The $55 million, 35-acre campus in Highlands Ranch, Colo., includes an academic building, athletic complex, and football and track stadium. At full capacity, the 9-12 grade school supports 1,200 students with a 20:1 student to teacher ratio.

Opened for the 2007-08 school year, the three-story Academic Building was the first of four buildings to emerge -- constructed in just 11 months. It contains 43 classrooms, eight science laboratories, administrative offices, and a 5,300-square-foot research and teaching media center with direct views of the Rocky Mountains. Sustainable design components for the 130,000-square-foot Academic Building include thermal displacement ventilation, low-flow/automatic restroom fixtures, and an advanced lighting/daylighting control system.

Valor's school leaders sought to "include ample amounts of natural light, which will provide a superior learning environment by helping students maintain alertness and interest." In addition, all buildings are designed to offer air quality and energy efficiency surpassing typical schools and creating a healthier facility. Eight months after opening, estimates indicated the school would use about half the amount of energy as a standard public school, saving an estimated $65,000 per year.

Enhancing the Academic Buildings' energy-efficient, daylighting features, outdoor light sensors limit the occupants' use of florescent bulbs when natural light is available. "Valor's large windows are engineered to maximize daylighting, while maintaining a comfortable interior climate. As an industry pioneer in energy-efficient, high-performance, thermal barrier products, Wausau's 3250 Series Heritage windows' were tuned to Colorado's climate and solar exposure," says Kevin Robbins, Wausau's regional sales manager.

Wausau's window frames were painted by Linetec in a durable, bronze finish and fabricated with recycled aluminum. Twenty percent of the facilities' materials are comprised of recycled content and 77% of the construction materials were diverted from landfills and to recycling programs. Regional suppliers and locally sourced materials were selected whenever possible. Colorado Window Systems of Denver installed Wausau's insulated window units to meet the school's quick-turn timeline, as well as its performance and sustainable design goals. Today, the windows allow students to enjoy outside views and a continued connection with the environment.

"The windows are energy efficient and provide proper lighting, yet remain aesthetically appealing. As the first private high school in Colorado to receive a LEED-Gold certification, we are very pleased to have partnered with a quality window manufacturer in Wausau," said Shannon L. Dreyfuss, executive vice president and CFO of Valor Christian High School.

Guided by the mission, "influence through excellence," Valor Christian High School formed its school board in 2005. The board purchased the future site of its campus in January 2006, and almost immediately selected SlaterPaull Architects Inc. of Denver to design the educational complex in collaborations with The Lund Partnership of Lakewood, Colo., and Anderson & Hastings of Denver. RMH Group provided additional, sustainable design and engineering recommendations. Saunders Construction Inc. of Englewood, Colo., served as general contractor and began construction on the Academic Building in September 2006.

Saunders' senior project manager, Dennis Disney, told the Associated General Contractors of Colorado, "A project of this scale typically requires an 18-month timeline, not including the four weeks we lost to inclement weather and snow removal." After the Academic Building's successful opening in August 2007, Saunders completed the athletic facility and chapel in October 2007 and the stadium in May 2008. Construction of the Arts and Aquatics facilities are planned for the near future.

Nationally recognized for its innovative expertise, Wausau Window and Wall Systems is an industry leader in engineering window and curtainwall systems for commercial and institutional construction applications. For more than 50 years, Wausau has worked closely with architects, building owners and contractors to realize their vision for aesthetic beauty, sustainability and lasting value, while striving to maintain the highest level of customer service, communication and overall satisfaction. Wausau is a part of Apogee Enterprises, Inc., a publicly held, U.S. corporation.